Mhs - Material Handling Supply Inc. Fundamentals Explained

Mhs - Material Handling Supply Inc. Fundamentals Explained

Blog Article

7 Easy Facts About Mhs - Material Handling Supply Inc. Explained

Table of ContentsThe Single Strategy To Use For Mhs - Material Handling Supply Inc.Mhs - Material Handling Supply Inc. for BeginnersThe Of Mhs - Material Handling Supply Inc.Some Known Details About Mhs - Material Handling Supply Inc. Mhs - Material Handling Supply Inc. - An OverviewTop Guidelines Of Mhs - Material Handling Supply Inc.

This line is called the line of activity. forklift rental near me. If the bottom of this line goes beyond the security triangle since a tons is too hefty or expensive, or since the forklift is out a degree surface area it will certainly topple. An upright line expanding from the center of mass of the vehicle-load mix should remain inside the security triangular to avoid the forklift from tippingThis stability triangle is made by connecting both front wheels and the pivot factor of the rear axle. The various other principle to comprehend is the forklifts center of mass. Notice that the front and back sides of the security triangle are high-lighted. When unloaded, the forklifts center of mass is ideal regarding below.

Heavier loads move the center of mass ahead also additionally. Raising the tons also shifts the center of mass onward. In order to avoid the lift from tipping, the consolidated facility of gravity of the tons and the lift must remain inside the stability triangle (at ground level) at all times.

Mhs - Material Handling Supply Inc. Fundamentals Explained

If you have a balanced tons, the tons is not likely to affect the side-to-side center of mass. https://www.goodreads.com/user/show/177800888-tanner-graves. But if you drive on a sloped surface area, your center of mass might pass exterior of the security triangular and the lift can tip. Every forklift has a recognition plate that notes crucial info concerning the truck

To be sure that the center of gravity of your forklift remains inside the security triangle, do not attempt to raise anything heavier than the identification plate permits. Regardless of exactly how active you are, you have to inspect your forklift prior to utilizing it. If you do locate something that can affect the security of the car you need to report it right away.

Follow the drivers manuals supplied by the devices manufacturer. These manuals define the secure procedure and upkeep of forklifts. Bear in mind, the driver is in charge of the secure procedure of the forklift. Do a pre-operation evaluation before every change. If the forklift is used all the time, evaluate it either prior to each change or after each change.

7 Easy Facts About Mhs - Material Handling Supply Inc. Described

It is completed in 2 components: the walk-around inspection, and, the seated assessment. OSHA does not call for documentation of an everyday inspection. It's an excellent idea to have a checklist to make certain you don't miss out on any steps. These lists can also be conserved as a part of the upkeep document.

If the forklift is an exterior forklift with pneumatic tires, inspect the air stress and look for extreme wear on the tires. A tire with low air pressure might cause the lift to tip when a lots is elevated.

Some Known Factual Statements About Mhs - Material Handling Supply Inc.

Look for fractures or various other indications of wear. Inspect all liquid degrees. Examine the engine for any type of indicators of wear, loosened links, or leakages. Clean up any extreme oil or other combustible substance. Try to find splits or defects in the forks, back-rest, mast, and overhanging guard. Check the recognition plate to ensure it is undamaged and readable.

Always start the engine while seated in the driver's positionnever while standing along with the forklift. Check all assesses and cautioning lights, and the battery or gas degree. Lift and lower the forks, and turn the mast.

Getting My Mhs - Material Handling Supply Inc. To Work

Check the brakes by depressing the brake pedal. Check the guiding. Relocate the forklift ahead a few feet.

Look for triggers or fires coming out of the exhaust system. If you discover anything incorrect with the forklift throughout the walk-around or seated evaluation, do not operate it until it has been fixed.

The Mhs - Material Handling Supply Inc. PDFs

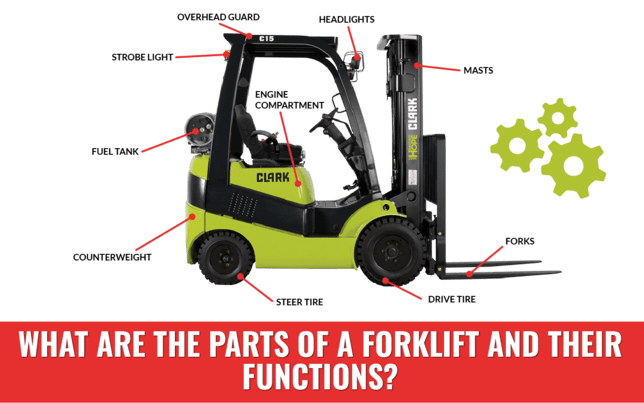

Forklifts have several relocating parts and pieces that allow the forklift to operate appropriately. Understanding the terminology of the parts and makeup of a forklift is crucial for effective communication with others while on the task - https://mhsinc30677.bandcamp.com/album/mhs-material-handling-supply-inc. Below are a few of the essential attributes and components that make up the composition of a forklift vehicle

For the majority of forklifts, the mast is developed towards the front of a forklift and directly in the forklift driver's line of vision. Forklift masts feature various sections that raise or reduced the forklift carriage along with the forks. These consist of:: Two pole phases: 3 mast phases: Four mast areas When choosing a forklift, it is essential to acquaint yourself with the different attributes and terminology of a forklift mast: the pole's lift elevation, the complimentary lift height and the prolonged height and the lowered elevation.

Report this page